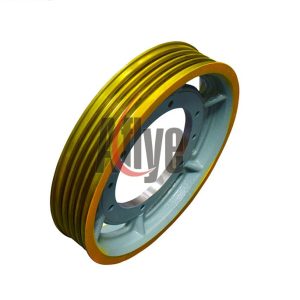

TGT300 Elevator Deflector Sheave

Size: D400*110mm*5 groove

Elevator Pulley Assembly Manual

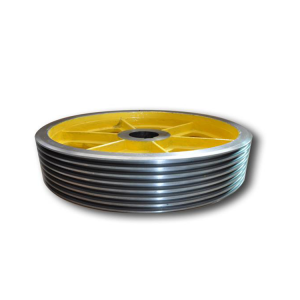

1. Characteristics of Elevator Pulleys

Elevator pulleys are designed to bear the weight of the elevator car and counterweights, as well as to change the direction of the wire rope's movement. Working in conjunction with the traction sheave of the elevator machine, the pulleys ensure the safe vertical movement of the elevator car.

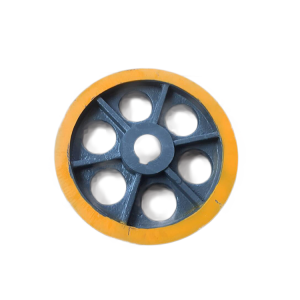

2. Production of Elevator Pulleys

- Cast the blank into shape.

- Process the blank into a semi-finished product using a CNC lathe.

- Assemble the semi-finished pulley, bearings, and shaft into a finished product using specialized equipment.

- Carefully package the pulley with foam and other materials to prevent damage and moisture during transport.

- Label the package with specifications, address, inspection status, and prepare for storage and shipment.

3. Usage of Elevator Pulley Assembly

When installing the elevator pulley assembly, handle it with care to avoid impact damage. After installation, apply anti-rust oil to the exposed parts of the shaft.

When installing the wire rope, ensure that the pulley groove and the wire rope remain in the same plane radially.

4. Maintenance of Elevator Pulley Assembly

- Inspect and clean the pulley groove surface monthly to ensure it is free of debris and soft materials.

- Check the anti-rust coating on the surface of the drive shaft monthly; if the coating has worn off or the anti-rust oil has dried out, reapply anti-rust oil promptly.

- Lubricate the pulley through the oil injection port every three months.

- If you hear significant noise from the bearings, add oil immediately. If the noise persists, replace the bearings promptly.