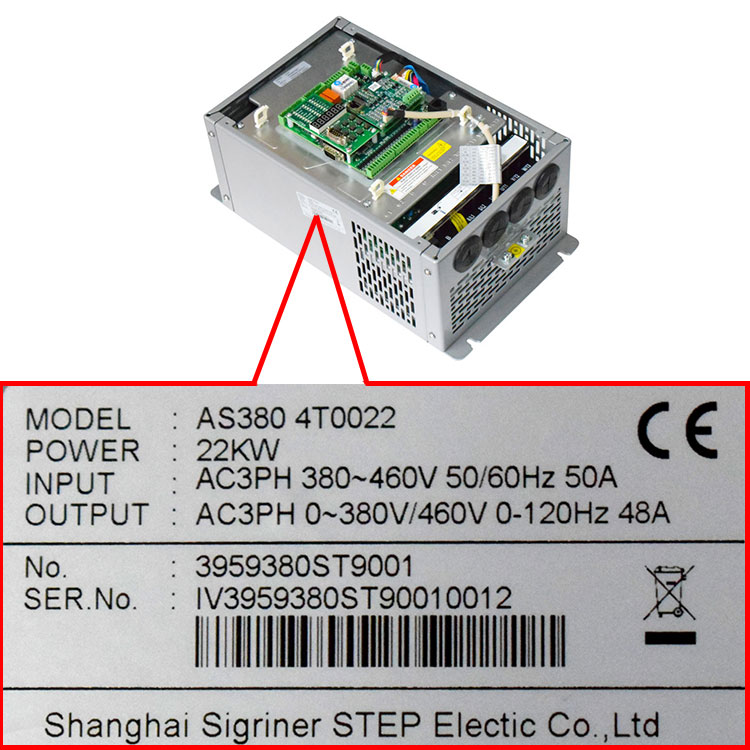

MODEL:AS380 4T0022

POWER:22KW

INPUT:AC3PH 380~460V 50/60Hz 50A

OUTPUT:AC3PH 0~380V/460V 0-120Hz 48A

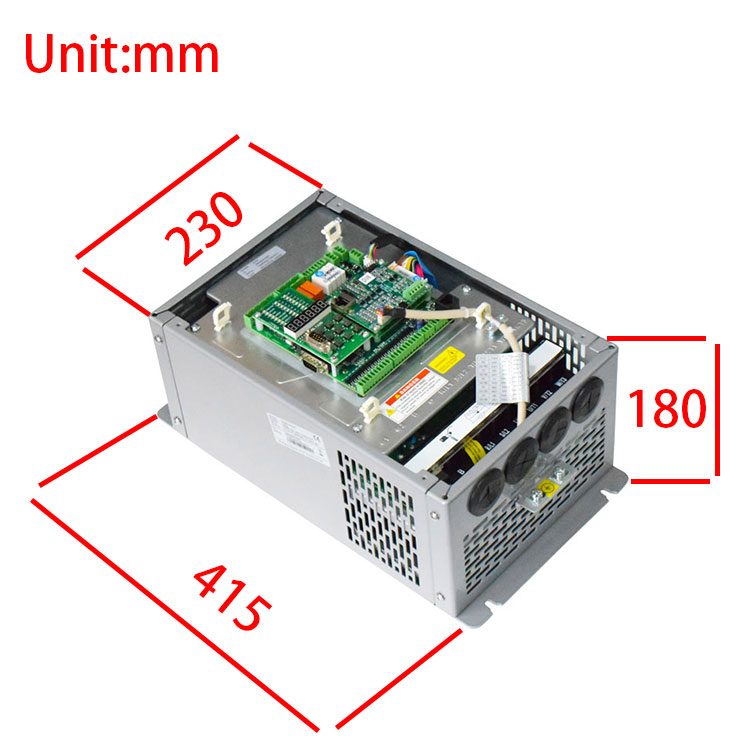

| AS380 Elevator Integrated Drive Controller | |||

| Model No. | Rated Power | Rated Current | Motor |

| AS380-2S01P1 | 2.3kVA | 6A | 1.1kW |

| AS380-2S02P2 | 4.6kVA | 12A | 2.2kW |

| AS380-2S03P7 | 6.9kVA | 18A | 3.7kW |

| AS380-4T02P2 | 4.7kVA | 6.2A | 2.2kW |

| AS380-4T03P7 | 6.9kVA | 9A | 3.7kW |

| AS380-4T05P5 | 8.5kVA | 13A | 5.5kW |

| AS380-4T07P5 | 14kVA | 18A | 7.5 |

| AS380-4T0011 | 18kVA | 27A | kW |

| AS380-4T0015 | 24kVA | 34A | 15kW |

| AS380-4T18P5 | 29kVA | 41A | 18.5kW |

| AS380-4T0022 | 34kVA | 48A | 22kW |

| AS380-4T0030 | 50kVA | 65A | 30kW |

| AS380-4T0037 | 61kVA | 80A | 37kW |

| AS380-4T0045 | 74kVA | 97A | 45kW |

| AS380-4T0055 | 98kVA | 128A | 55kW |

| AS380-4T0075 | 130kVA | 165A | 75kW |

AS380 Elevator Integrated Drive Controller Technical Characteristics

– It is the organic combination of elevator control and drive. The whole device has compact structure, small volume, less wiring, high reliability, easy operation and more economical.

– Dual 32-bit embedded microprocessors work together to complete the elevator operation function and motor drive control.

– Redundant safety design. Both the control computer and the drive computer have safety protection functions, which greatly improves the safety factor of the elevator.

– The anti-interference capability is designed to exceed the *higher level of industrial design requirements.

– Full CAN serial communication. The whole system has simple wiring, strong data transmission capability and high reliability.

– Adoption of advanced direct stopping technology makes the elevator run more efficiently.

– With rich and advanced elevator operation functions, it can fully meet the various needs of customers.

– With advanced group control function, it not only supports the traditional group control mode of * more than eight units, but also supports the novel group control mode of destination floor assignment.

– Adopting advanced vector control technology. Excellent motor speed regulation performance, realizing *best comfort.

– Good versatility, applicable to both synchronous and asynchronous motors.

– Newly invented load-sensorless starting compensation technology enables the elevator to have excellent starting comfort without installing a weighing device.

– Incremental ABZ encoders can be used for synchronous motor control, and the same load-sensor-free start-up compensation technology can be used for excellent start-up comfort.

– The new PWM deadband compensation technology effectively reduces motor noise and motor losses.

– Dynamic PWM carrier modulation technology, effectively reducing motor noise.

– If the motor parameters are set accurately, the asynchronous motor does not need self-learning of motor parameters. If the site can not know the precise motor parameters, can also be used in a simple static motor self-learning way to make the system automatically obtain the accurate parameters of the motor, without lifting the car and other complex work.

– The hardware adopts the new module of the 6th generation, the junction temperature resistance can reach 175℃, the switching and opening loss is low, and the service life is prolonged.