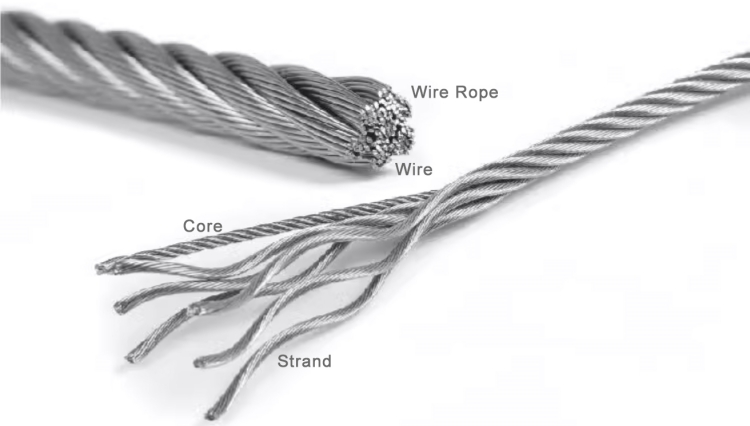

The definition of Steel Wire Rope

Steel wire rope is composed of few metal wires twisted into a helix according to certain rules. We can divide it into various types by different ways of classification. But by its very nature, it consists of rope-making wire, the core and rope grease. Elevator steel wire rope plays an important role in the elevator system by acting as a loading component. It carries almost the entire weight of whole elevator which means the quality of it will directly affects the safety of the elevator’s operation.

Factors affecting the service life of Elevator Steel Wire Rope

Not to mention, the correct selection, use and maintenance of elevator steel wire rope are important for the safety and normal operation of the elevator. They are also important for extending the service life of the rope. Generally the dynamic tensile force has a strong affect on wire rope’s service life.

Furthermore, the service life of elevator wire rope is also affected by the unevenly distributed load. Even if the same batch of elevator steel wire rope from the same manufacturer may have different service life. Some have a life span of 5 years, while others have a life span of 10 years. This is not only because of the impact of the quality of wire rope itself but also the uneven stretching force of wire rope.

Elevator steel wire rope mainly include traction machine wire rope, speed governor wire rope, compensation wire rope and door operator wire rope. Here are some of our products in this regard and their specific parameters. Hope this can help you choose the right wire rope and use it correctly.

8-Strand Seale Type Independent Wire Rope Core (1570/1700MPa Right Hand Regular Lay)

- Suitable for Type-U/Type-V Traction Groove

- High degree of Minimum Breaking Load

- Uniform diameter and roundness give strong resistance to deformation

- Pre-stretching on rope-closing machine

- High standard of Modulus of Elasticity with small permanent extension

- High expectation of fatigue life

- Suitable for medium and high speed traction machine elevator and hydraulic elevator

| Nominal Diameter (mm) | Minimum Breaking Load(kN) | Reference Weight(kg/100m) | Part NO. | |||

| All-Steel Core | Composite-Steel Core | All-Steel Core | Composite-Steel Core | All-Steel Core | Composite-Steel Core | |

| 8 | 38.0 | 36.9 | 26.0 | 24.6 | BT532-8 | BT633-8 |

| 10 | 59.5 | 57.6 | 40.7 | 38.5 | BT532-10 | BT633-10 |

| 12 | 85.6 | 83.0 | 58.6 | 55.4 | BT532-12 | BT633-12 |

| 13 | 100 | 97.4 | 68.8 | 65.1 | BT532-13 | BT633-13 |

| 16 | 152 | 147 | 104 | 98.6 | BT532-16 | BT633-16 |

8-Strand Warrington Type Wire Rope (1570MPa Right Hand Regular Lay)

- Suitable for Type-U/Type-V Traction Groove

- High degree of Minimum Breaking Load

- Uniform diameter and roundness give strong resistance to deformation

- Pre-stretching on rope-closing machine

- High standard of Modulus of Elasticity with small permanent extension

- High expectation of fatigue life

- Suitable for medium and high speed traction machine elevator and hydraulic elevator

| Nominal Diameter (mm) | Minimum Breaking Load(kN) | Reference Weight(kg/100m) | Part NO. |

| 8 | 35.8 | 26.0 | BT542-8 |

| 10 | 55.9 | 40.7 | BT542-10 |

| 12 | 80.5 | 58.6 | BT542-12 |

| 13 | 94.5 | 68.8 | BT542-13 |

| 16 | 143 | 104 | BT542-16 |

9-Strand Filler Type Wire Rope (1570MPa Right Hand Regular Lay)

- Suitable for Type-U Traction Groove

- High degree of Minimum Breaking Load

- Uniform diameter and roundness give strong resistance to deformation

- Pre-stretching on rope-closing machine

- High standard of Modulus of Elasticity with small permanent extension

- Slight contact stress with rope sheave

- Extreme length of fatigue life

- Suitable for medium and high speed traction machine elevator

| Nominal Diameter (mm) | Minimum Breaking Load(kN) | Reference Weight(kg/100m) | Part NO. | |

| 9x21Fi | 9x25Fi | |||

| 10 | —— | 66.0 | 42.8 | BT572-10 |

| 11 | —— | 79.9 | 51.8 | BT572-11 |

| 13 | —— | 111.6 | 72.3 | BT572-13 |

| —— | 16 | 174 | 110.0 | BT562-16 |

| —— | 18 | 220 | 139 | BT562-18 |

9-Strand Seale Type Fiber Core Wire Rope (1370/1770MPa or 1620/1770MPa Right Hand Regular Lay)

- Suitable for Type-U/Type-V Traction Groove

- Remarkable achievement at abrasion resistance

- Uniform diameter and roundness

- Pre-stretching on rope-closing machine

- High standard of Modulus of Elasticity

- Enhancing 30% in fatigue life than normal products

- Suitable for medium and high speed traction machine elevator

| Nominal Diameter (mm) | Minimum Breaking Load(kN) | Reference Weight(kg/100m) | Part NO. | |||

| 1370/1770 | 1620/1770 | 1770 | 1370/1770 | 1620/1770 | ||

| 8 | 28.1 | 30.8 | —— | 21.8 | BT130-8 | BT230-8 |

| 10 | 44.0 | 48.1 | —— | 34.0 | BT130-10 | BT230-10 |

| 12 | 63.3 | 69.2 | —— | 49.0 | BT130-12 | BT230-12 |

| 12.7 | 70.9 | —— | —— | 54.8 | BT130-12.7 | —— |

| 13 | 74 | —— | 87.6 | 57.5 | BT130-13 | —— |

| 16 | 113 | —— | 133 | 87.0 | BT130-16 | —— |

Why choose us?

A-fly International Limited has committed to producing elevator&escalator spare parts for over 20 years. Come and get our products to upgrade your equipment in order to ensure the safety of your home or business. We provide high quality products with awesome price. Perfect after-sale service offered as well.