AQ32KB safety gear is single wedge progressive safety gear,which has characteristics as stability function,safety usage reliability,easy for installtion and maintannance ect. This type of safety gear could be used as the new generation elevator safety component product ,also could be used for regenerate the out of date elevators

Main technical specifications:

| Rated speed | 0.2-2.0m/s |

| Max running speed | 2.89m/s |

| Permissible groos mass:(P+Q)1 | 1200-2700kg |

| Type of spring component | disc spring |

| Guide rail surface width | 9,10,15.88,16mm |

| Machined guide rail hardness | 115-143 HB |

| Guide rail machined style | Machined、Cold drawn |

| Machined guide rail surface roughness | lateral 0.8um≤Ra≤3.2um vertical Ra≤1.6um |

| Guide rail ribrication | lubrication and nunlubrication |

| Lubrication requirements(enviorment stable) | -5~35℃: ISO VG 320、ISO VG 100 |

| Use for | car/counterweight |

| Net weight/pair | 6.4 kg |

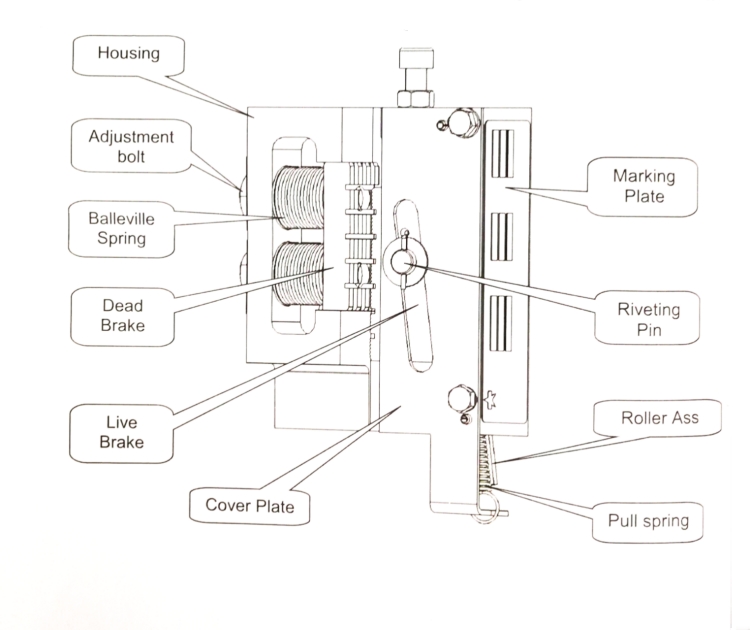

Contruction instrction:

AQ32KB safety gear is using the belleville spring and the single wedge pulling

construction. When the elevator goes down,the running speed is over the rated and

gets the governor tripping speed, the operation system of the gear will make

the gripping wedge move upwards on the bevel of the gear through pu;;ing plate.

When the gripping wedge connects the guide rail, the frication will be

generated. the gripping wedge move upward on the bevel of the gear

continuously and pull the car deviation to eliminate the distance between

guide rail and the gripping wedges will grip the guide rail,then control the car

deceleration by frication made through the wedge and guide rail

How To Quickly Install Elevator Safety Gear?

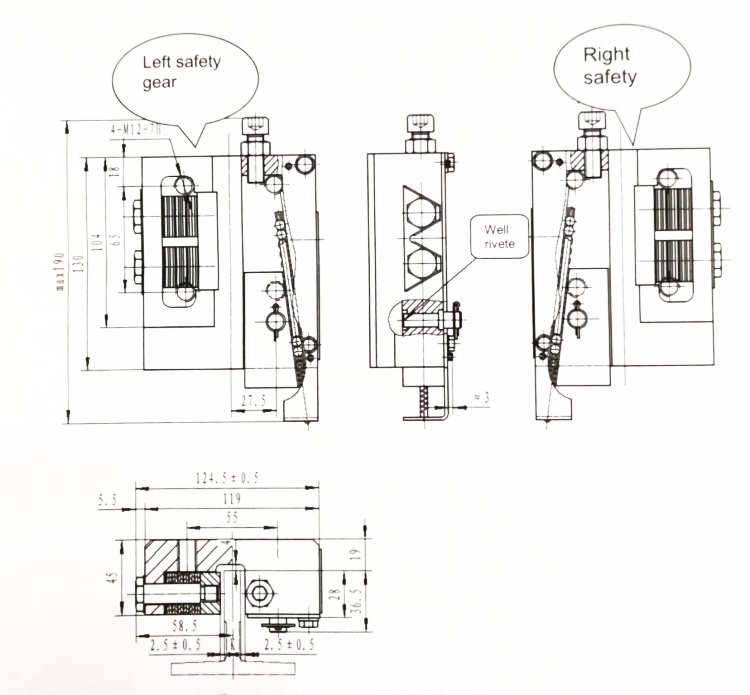

- Fasten the safety gear to the special use bracket (or bottom beam) with 4XM12 bolt, no overtone

- Install the guide rail to the bottom of safety gear specical use bracket (or bottom beam) with bolts and screws

- Adjust the position of safety gear and gudie rail shoes, ensure the equally distance bewteen the two wedges of the safety gear to both sides of the guide rail around 2.5±0.5mm.Make sure the guide rail shoes sleeve connect to the guide rail surface,.Fasten the bolt and the screws after adjusting.

- Fasten the pull rod and the riveting pin of the gripping wedge and bix with cotter pin