How To Choose Escalator Steps?

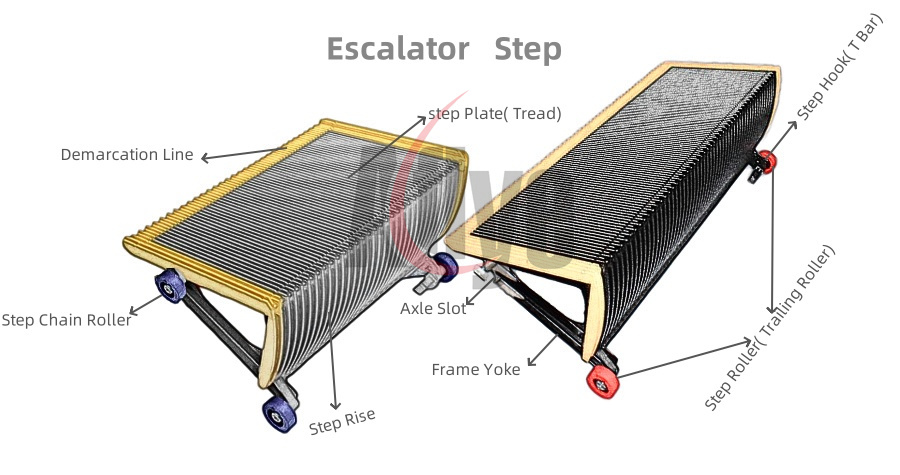

Escalator step system mainly includes: step tread (step plate), demarcation lines, step riser, step chain roller, step trailing roller, axle slot, frame yoke, step hook (T bar) and so on. And the escalator step is the moving part on which a passenger is carried safely. The Passengers just need to stand on the step, then the escalator will carry them to their destination. It is the most important parts of escalators.

The Step Plate (Tread) is the surface area of the step people step on. The step plate is usually made of an aluminium plate with longitudinal cleats or grooves that run through the combs and provide secure footing.

The Escalator Step Riser is the vertical cleat cast into the front of a step, designed to pass between the cleats of adjacent step, thus creating a combing action with minimum clearance for safety.

The Demarcations are yellow strips or may be in bold colour around the step tread but mostly located at the front and at the rear ends of the tread. They are used to visually locate the step separation and visual contrast between the steps and the combs.

Frame / Yoke – Main support for riser, step tread, and step wheels

Trail Wheels are used to guide the step and support its load on the track and prevent it from being out of plane.

Step Hook normally attached to the end of the yoke by the step wheel used to activate the step up thrust safety device when the steps are not on their plane of travel at the top and bottom inclines.

Escalator Step Dimensions:

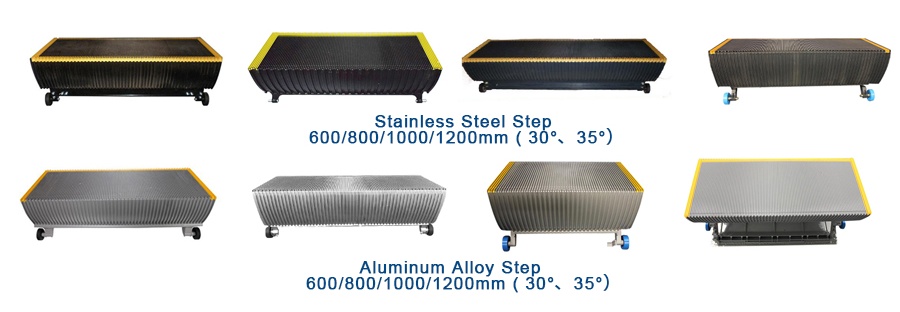

Escalator Step dimensions are usually including 600mm, 800mm, 1000mm,1200mm and other specifications to adapt to the needs of different places.

How to choose Escalator Step?

There are two main types of step materials,including aluminum alloy and stainless steel material.

Escalator aluminum alloy casting steps are usually divided into integral die-casting steps and Assembled steps. These steps are characterized by their light weight, high quality appearance and ease of manufacture, assembly and maintenance. As well as the price of aluminum alloy escalator steps are more affordable.

Escalator stainless steel step: High strength, good corrosion resistance, wear-resistant, easy to maintain, but heavier weight, relatively high cost, processing difficulties.Mainly for indoor type. Step height of not less than 0.24m, depth of not less than 0.38m.

In general, aluminum alloy material is more suitable for the weight and aesthetic requirements of higher places, while stainless steel material step is more suitable for strength and wear resistance requirements of higher places. Choosing which material, should be according to the use of the environment and demand to decide.