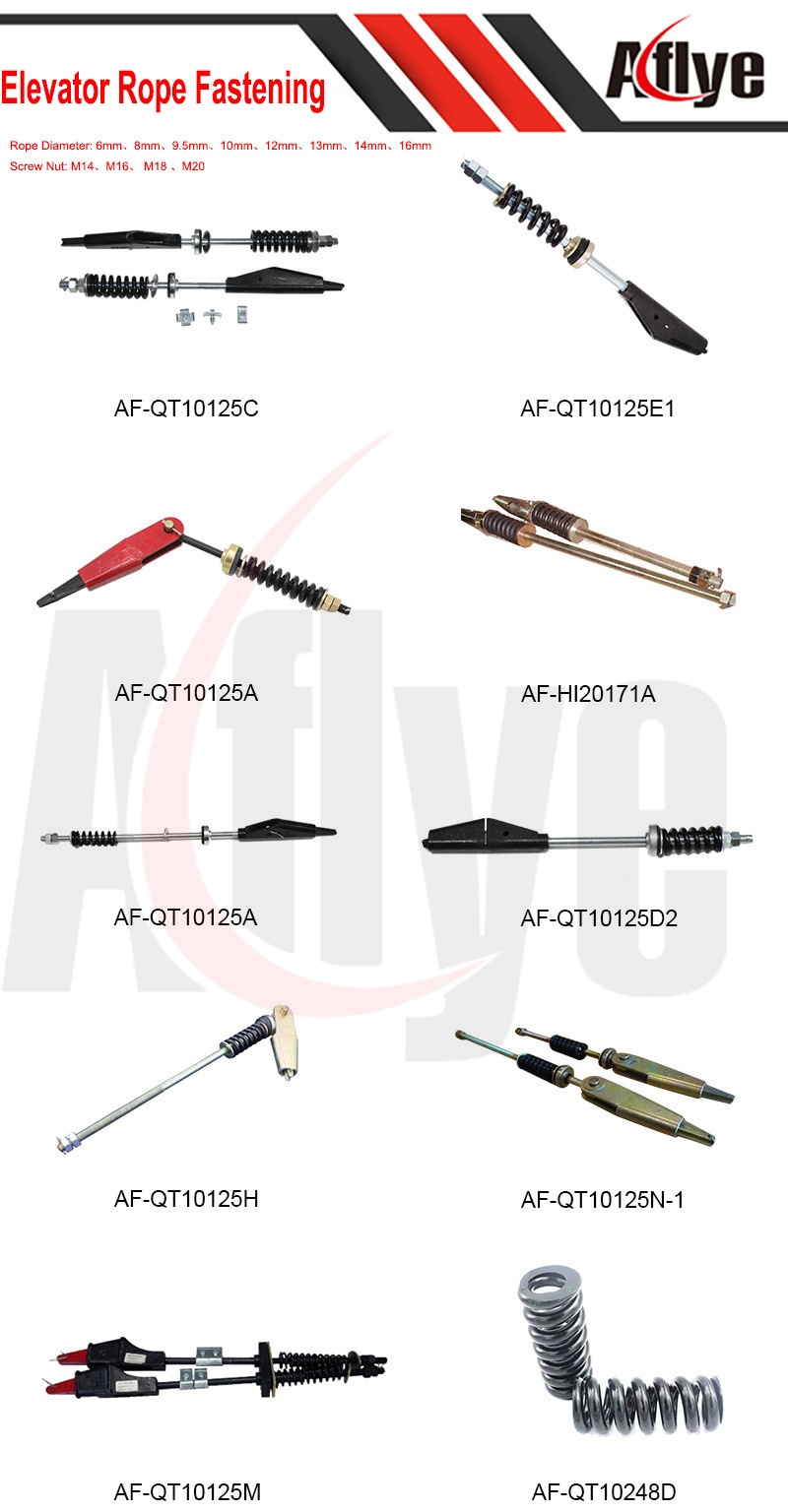

The elevator rope fastening, also known as the traction rope tapered socket, is a critical component in the elevator traction system. Its primary function is to connect the traction wire rope to the elevator car and counterweight device, or to the traction machine’s load-bearing beam and rope termination plate, serving as a transitional connection.

Structure and Function

The elevator rope fastening is typically made of high-strength materials, providing excellent load-bearing capacity and wear resistance. Its design allows for easy installation and removal, ensuring the stability and safety of the traction wire rope during operation. Additionally, the tapered socket incorporates anti-loosening and anti-detachment features to prevent any risk of loosening or falling off during elevator operation.

Application Scenarios

The elevator lift rope fastening is widely used in various elevator systems, including passenger elevators and freight elevators. Its application not only enhances elevator performance but also improves safety by reducing failures and potential hazards caused by loose connections.

Conclusion

Understanding the different types of wire rope fastening and its characteristics is essential for ensuring elevator safety and enhancing ride comfort. Selecting the right wire rope fastening contributes to the longevity and reliability of the elevator system.