What is a buffer in an elevator?

Elevator Buffer is a safety mechanism device designed to absorb and dissipate the energy generated during the car’s descent or an impact, typically at the bottom of the elevator shaft.

What is the stroke of the elevator buffer?

Elevator Buffer Types are mainly including :energy-storing buffers and energy-dissipating buffers. The stroke of the elevator buffer depends on the elevator’s rated speed and the type of buffer.

Energy-Storing Buffers

Rated Speed Limitation:

Energy-storing buffers can only be used for elevators with a rated speed of no more than 1.0 m/s.

Buffer Stroke: Typically ranges from 200 mm to 350 mm.

Energy-Dissipating Buffers

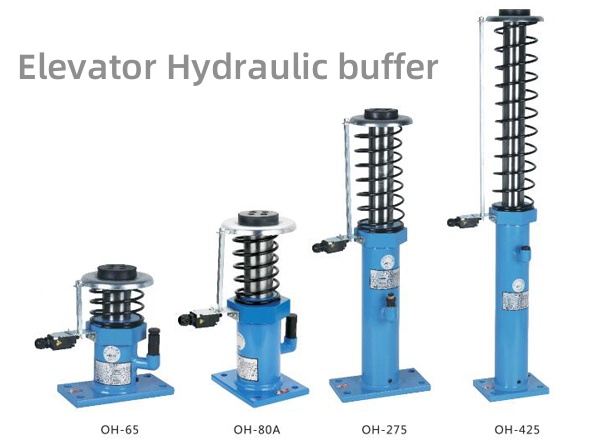

Energy-dissipating buffers, such as hydraulic buffers, are suitable for elevators with any rated speed.

Requirements: When the elevator car, carrying its rated load, falls freely and impacts the buffer at the design speed, the average deceleration should not exceed 1g. Additionally, the time during which the deceleration exceeds 2.5g should not be longer than 0.04 seconds.

Buffer Stroke: Typically ranges from 150 mm to 400 mm.

The main difference between these two types is that energy-dissipating buffers (like hydraulic buffers) are designed to handle higher speeds and provide a more controlled deceleration, while energy-storing buffers are primarily used for lower-speed elevators and rely on mechanical energy storage for impact absorption.

Elevator buffer is a critical safety component that ensures the smooth operation of the elevator and protects both passengers and the elevator system in case of a malfunction or extreme operating conditions. Choosing a high-quality buffer adds a strong layer of protection to your machinery, making its operation smoother, safer, and quieter.