- admin@aflye.com

- +86-20-34379130

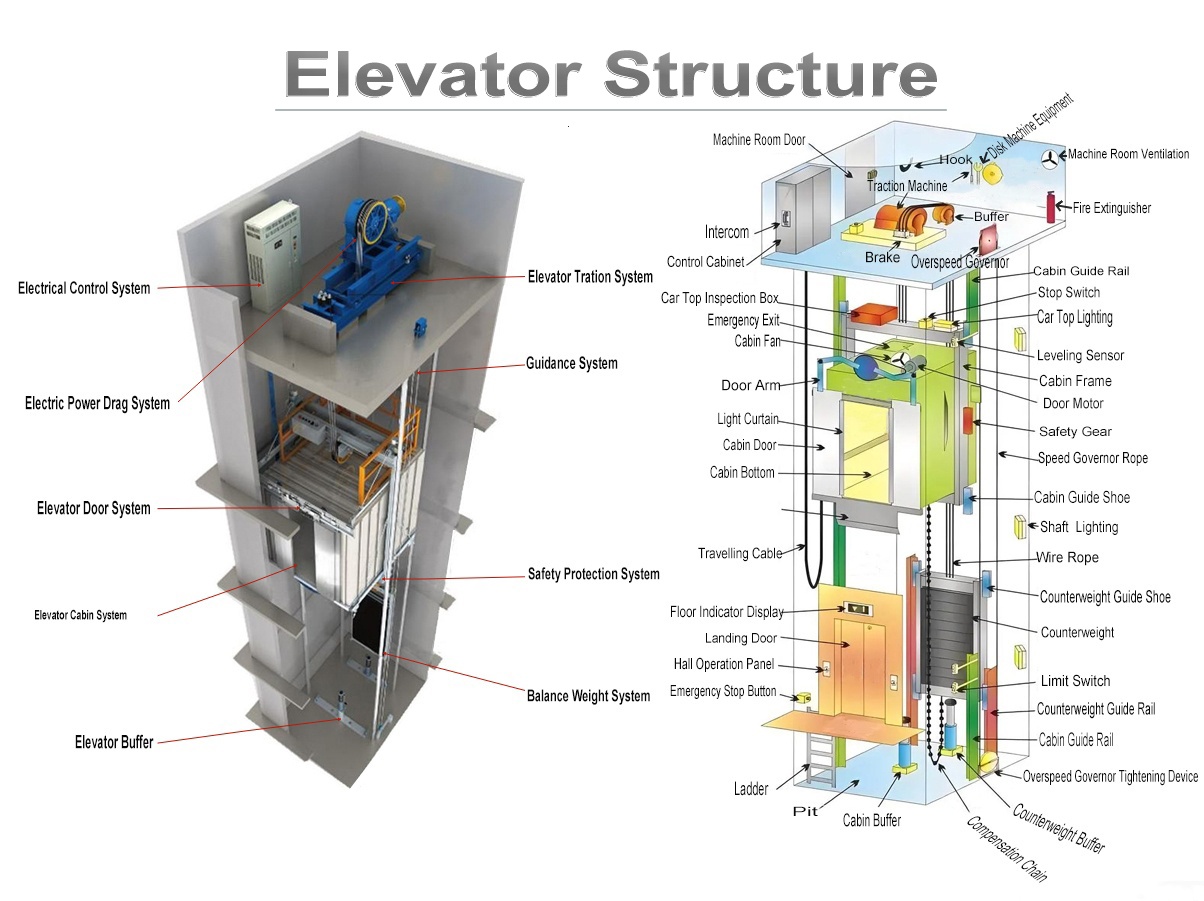

Our Elevator & Escalator Parts Meet Diverse Needs, Promote Sustainable Social Development

Professional Elevator & Escalator Parts Supplier With Over 25 Years Of Experience,Which Meet Different Needs

Elevator & Escalator Parts Manufacturer And Supplier

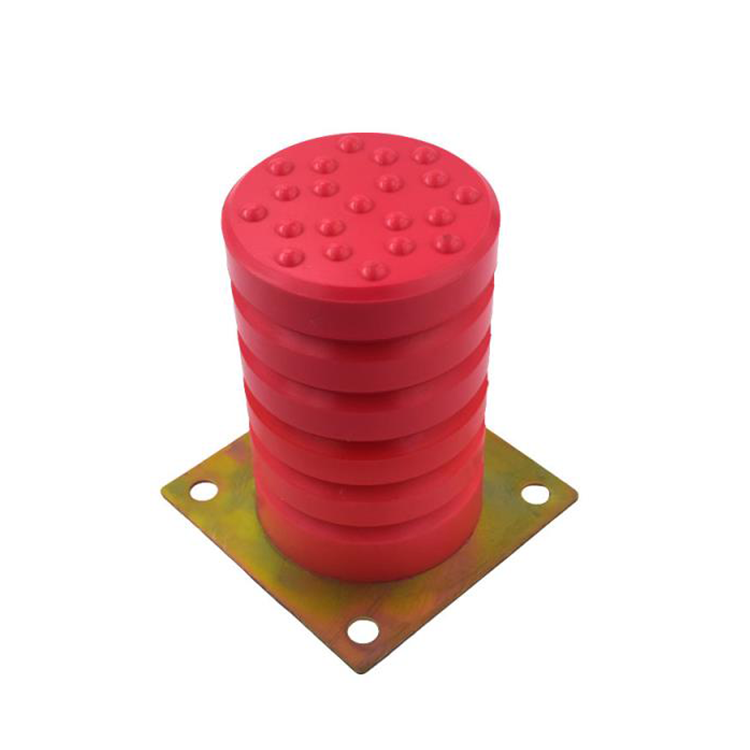

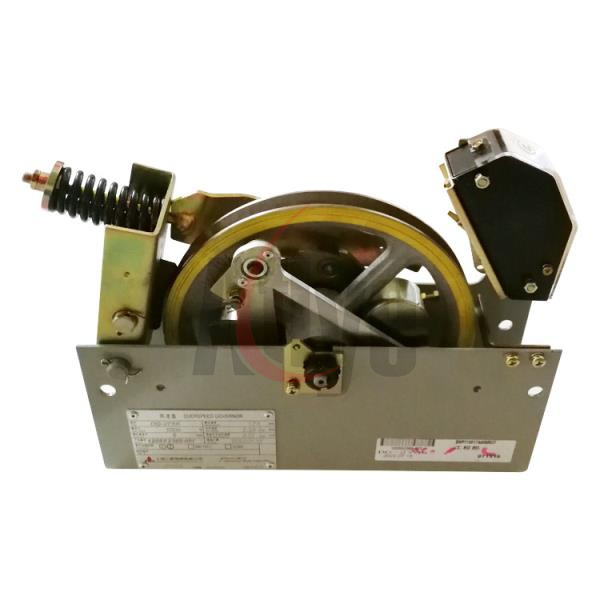

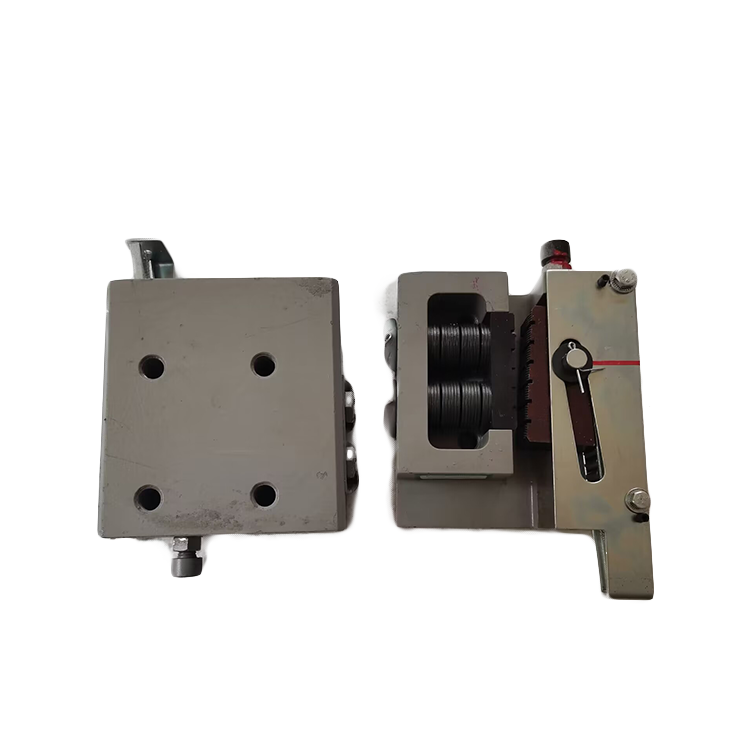

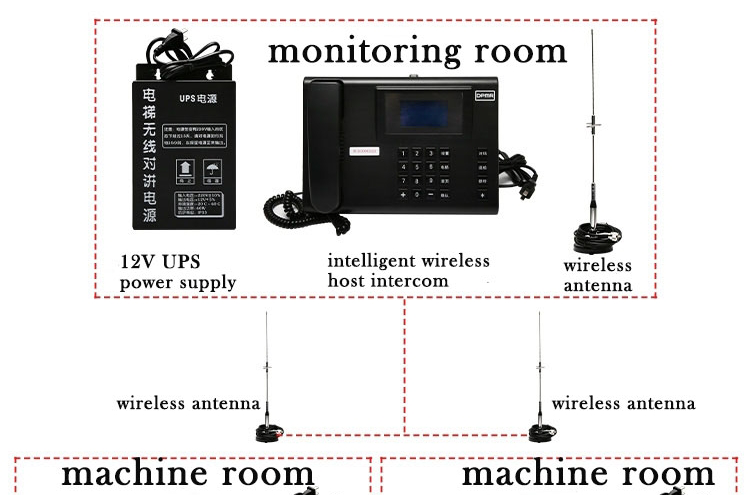

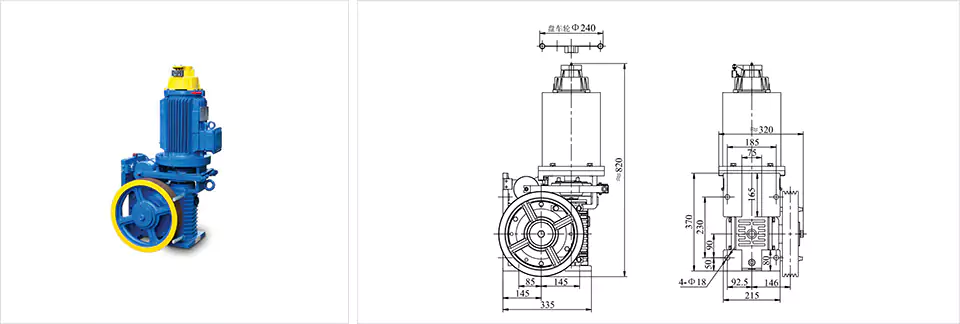

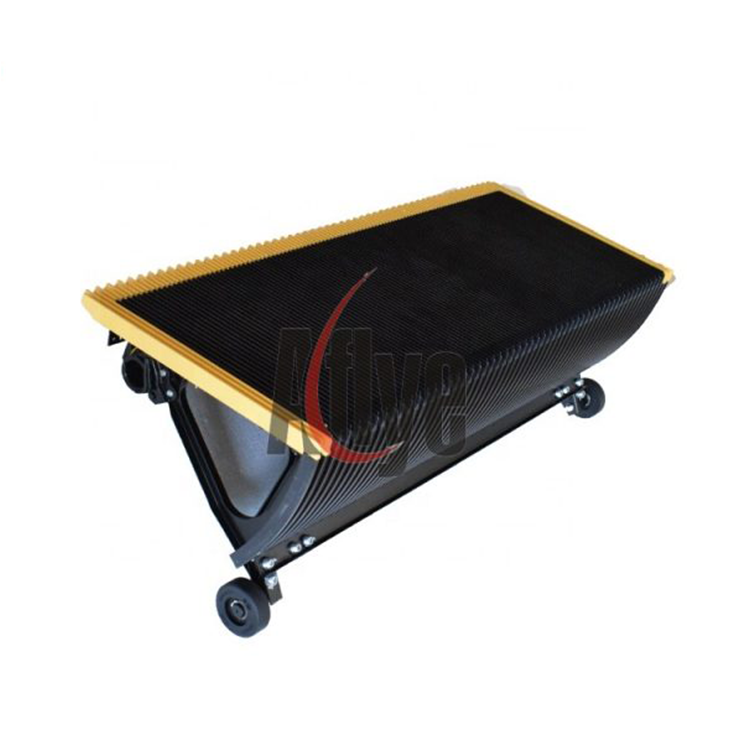

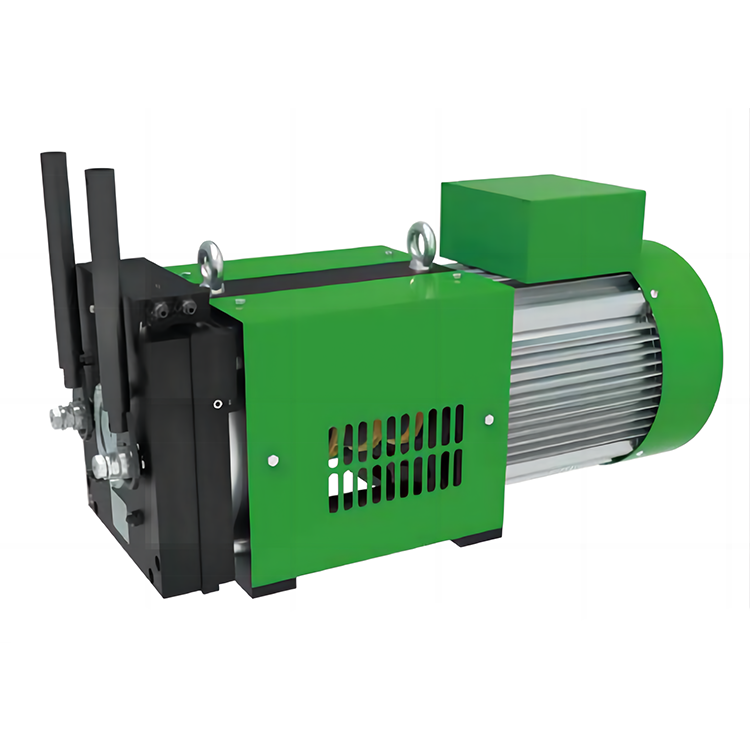

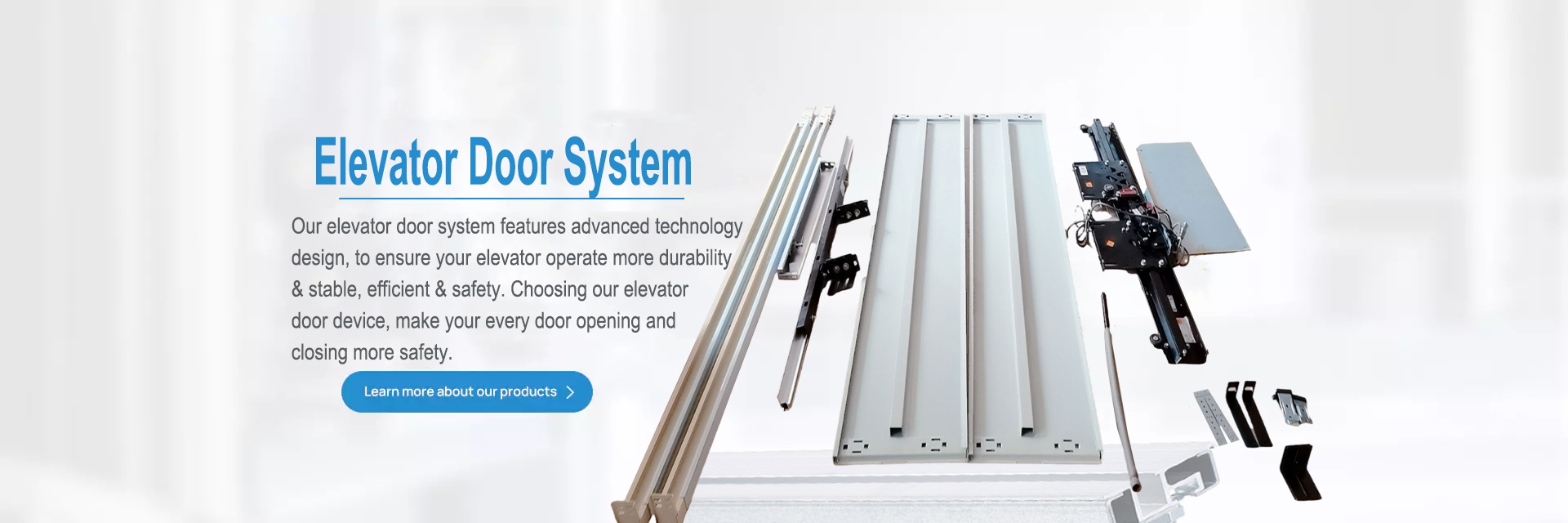

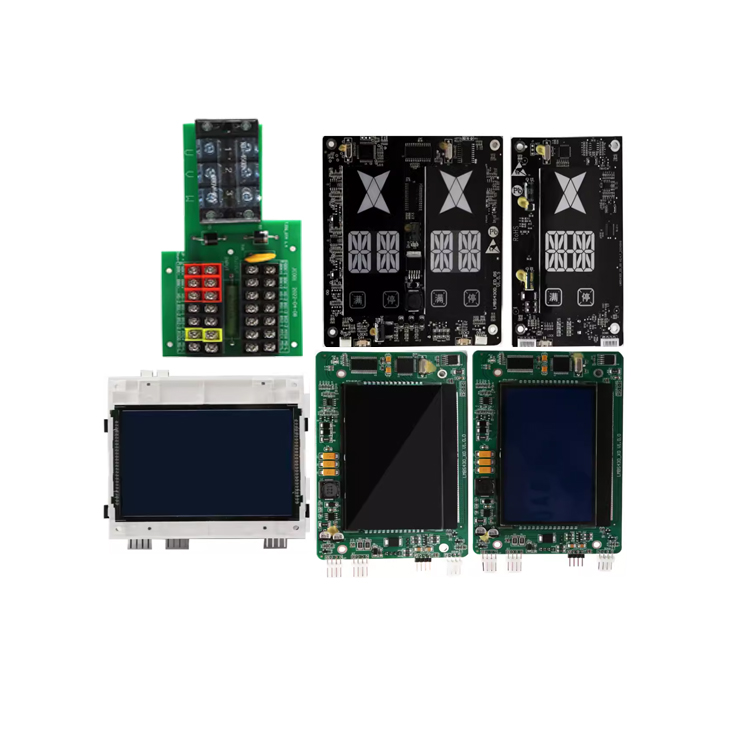

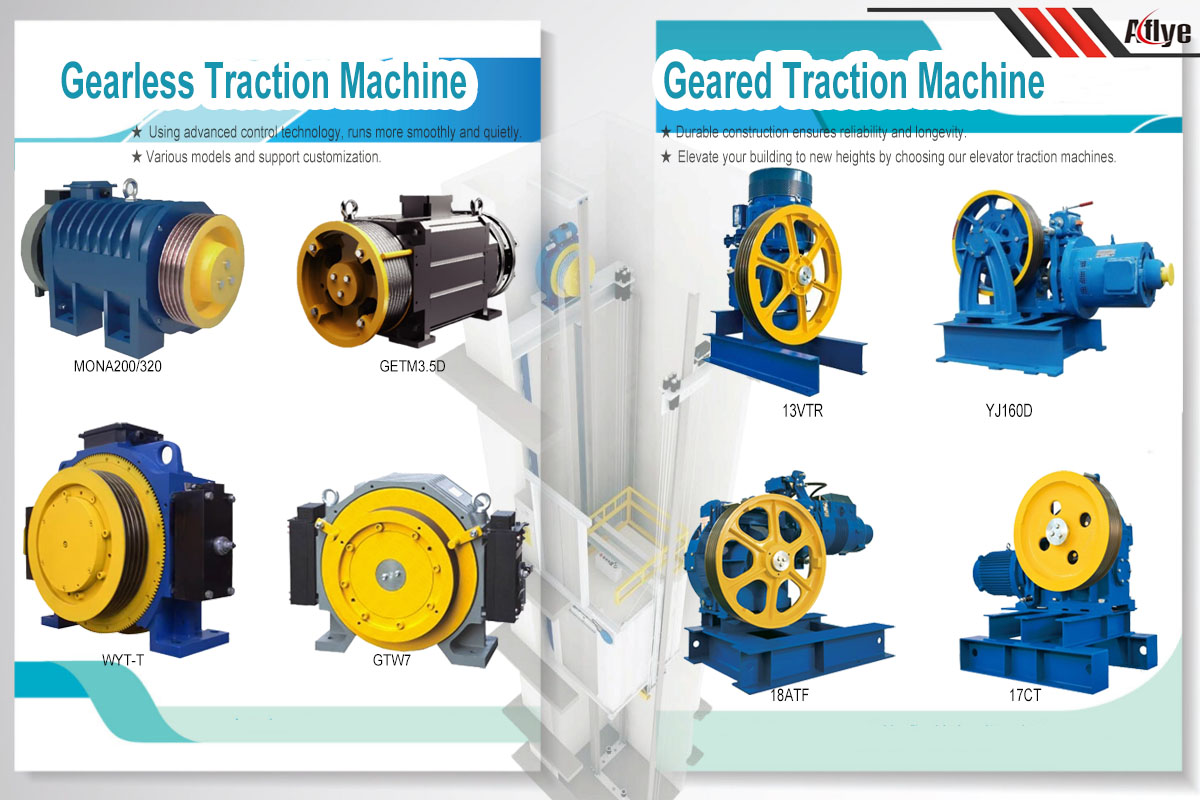

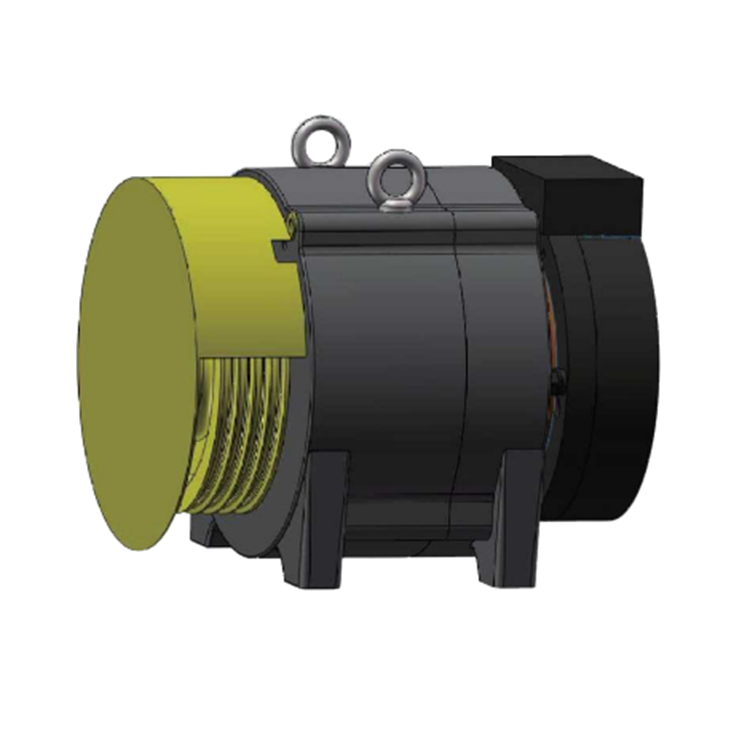

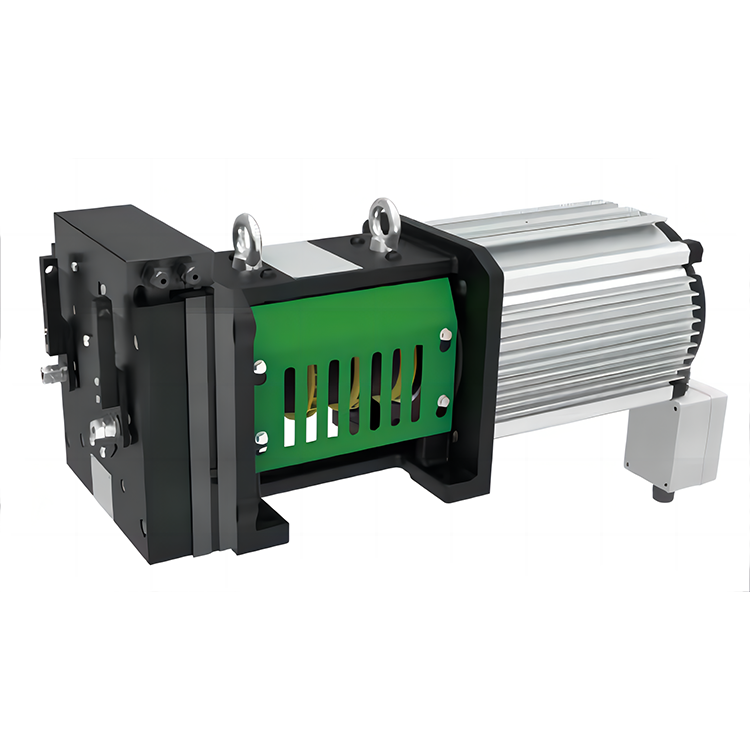

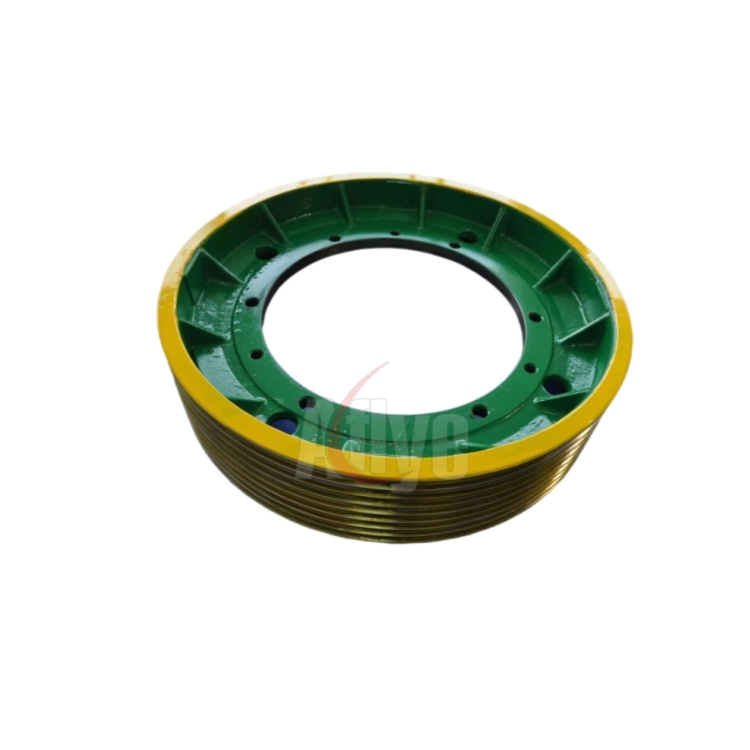

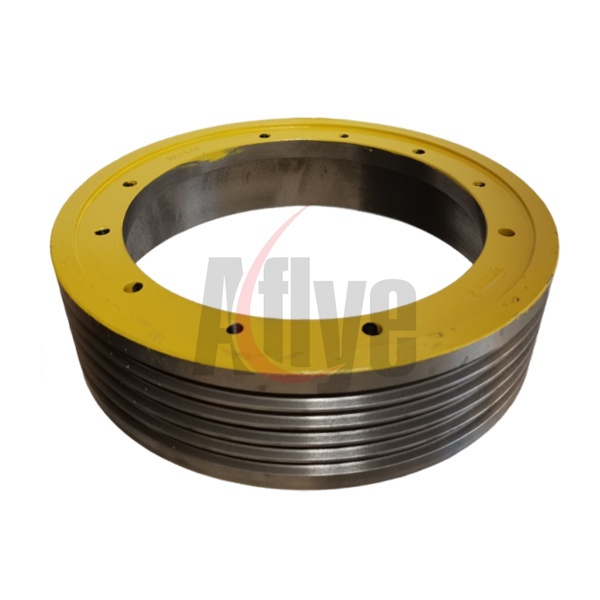

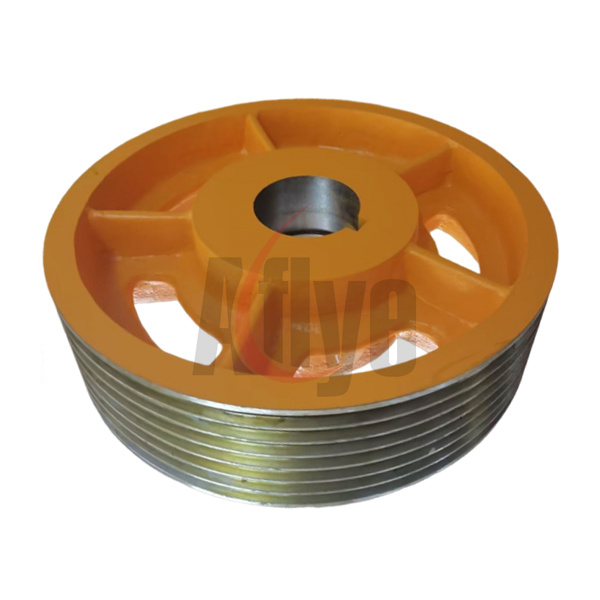

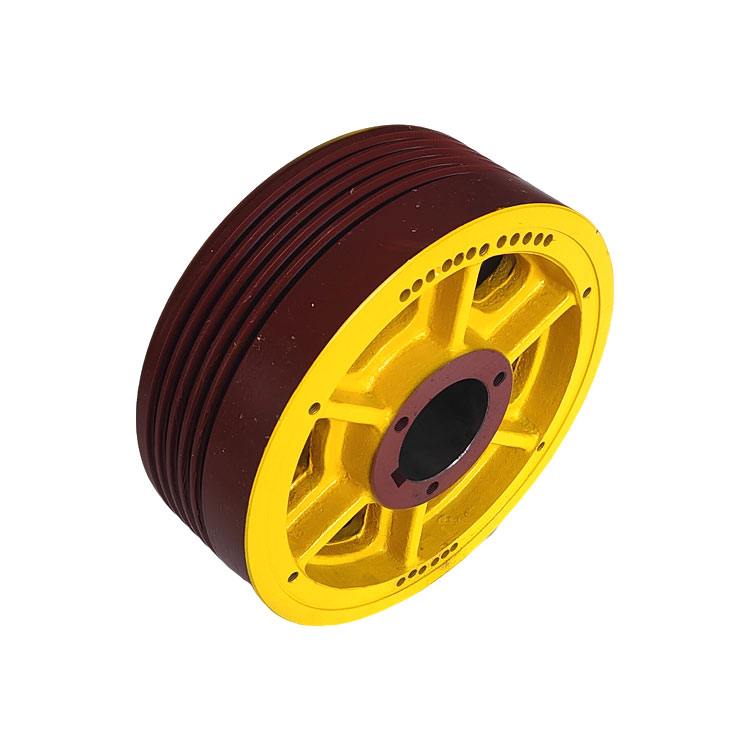

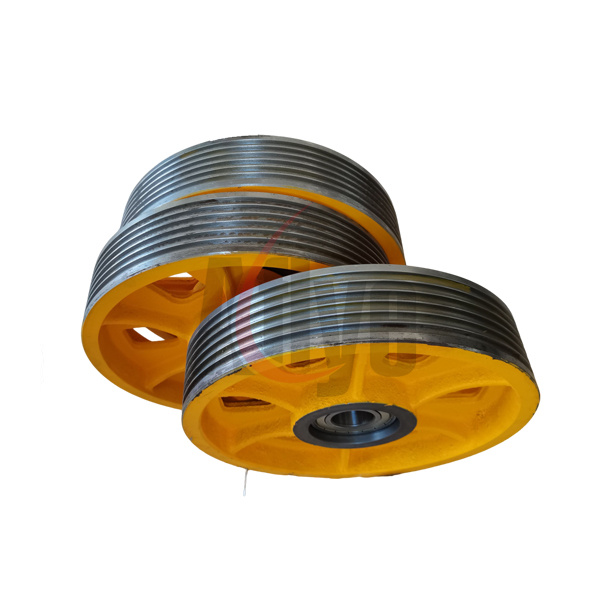

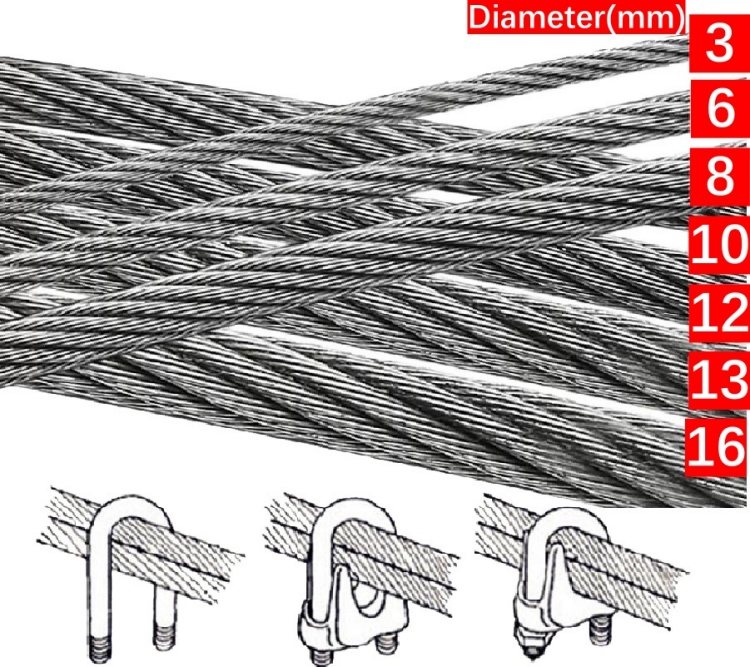

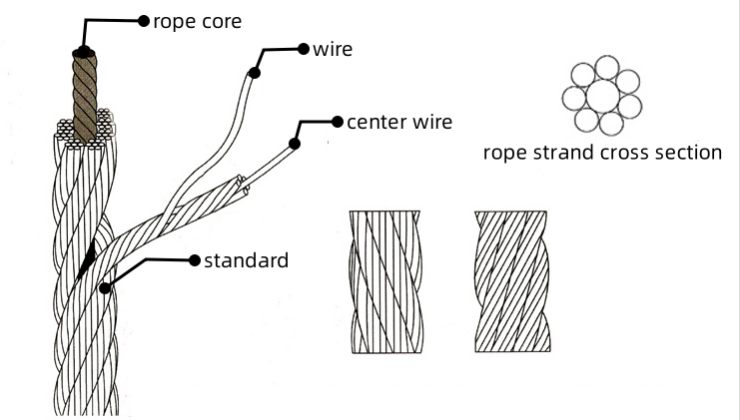

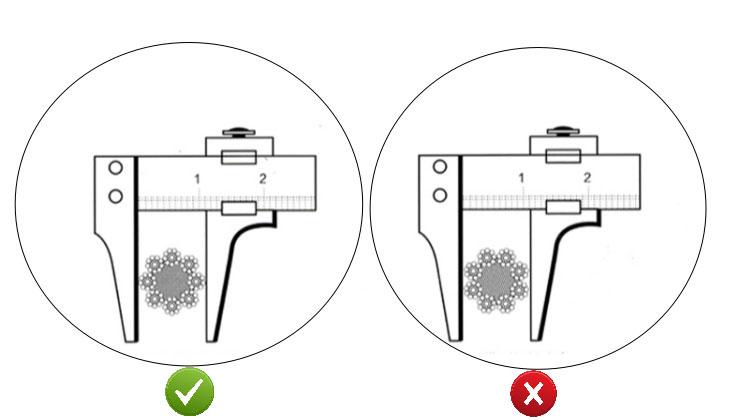

We produce more than 20,000 types of spare parts, covering over 12 major elevator and escalator brands. There is always the product you need.

Request Materials/Enquiries

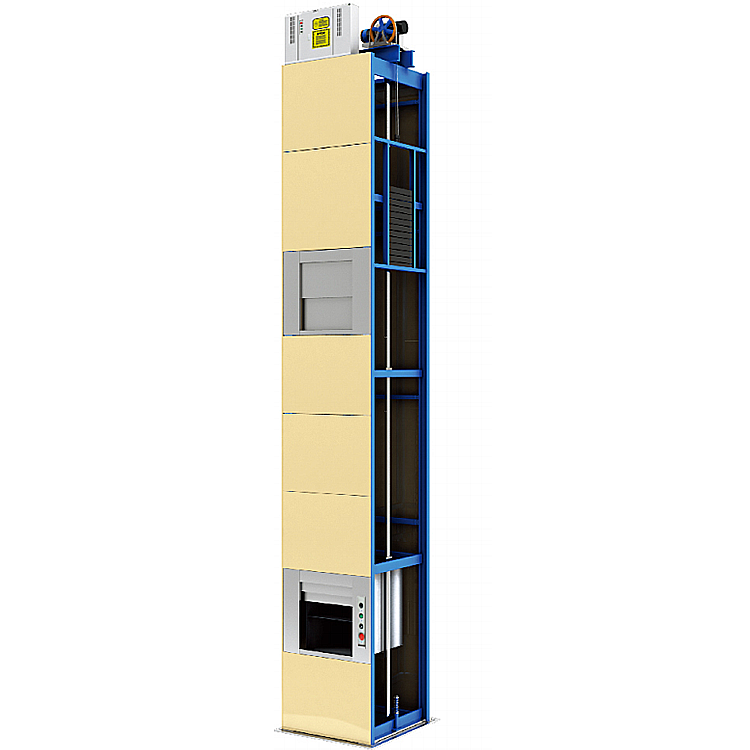

Application

With widely used in various fields,our products sell well in more than 200 countries and regions,and are highly favored by customers.

Company Advantages

A-FLY, is a leading supplier of high-quality elevator & escalator parts, offering a comprehensive range of products. With a focus on safety and durability, we serve clients worldwide, ensuring efficient and reliable escalator operations through our premium parts and exceptional customer service.

Extensive Product Range

As a global supply chain company,we offer varieties of elevator & escalator parts and ensure products availability and cost efficiency to meet diverse customer needs.

Technology Innovation

We are staying at the forefront of technological advancements by regularly introducing innovative parts and solutions. And providing 24/7 customer service to assist with urgent inquiries and orders

Logistics & Distribution

We are always maintaining well-stocked warehouses to ensure rapid availability of parts and providing real-time tracking of orders and transparent logistics communication to keep customers informed.

Customer Relationship

We place great importance on maintaining strong relationships with our clients, listening to their feedbacks, addressing their needs promptly to ensure mutual success and satisfaction.

Problems You May Encounter

We consistently exceed the needs and expectations of our customers and partners.

Do you offer warranties on your products?

Yes, most of spare parts come with one year warranty from the date of purchase. Different parts warranty periods are different. If you need further details about the warranty or have any other questions, please feel free to contact our customer support team.

Do you offer discounts for bulk purchases?

Yes, we provide discounts for bulk orders. Please contact our sales team for a custom quote list.

What should I do if I received a damaged or defective item?

Please contact us within 48 hours of receiving a damaged or defective item. We’ll arrange for a replacement or refund.

View More

.png)

-e1731921718784.png)

-e1732093859742.png)